in a few easy steps, bring your ideas to life.

How It Works

From single prototypes to high quantity production parts, we’ve got you covered

Upload Model

Click through to the quote form. Upload your STEP, STL, STP, SLDPRT, or X_T file. If you have more than one, please ZIP them up before uploading.

Choose Material

Select a material based on the properties and finish you’re looking for. If we don’t have a particular material, please choose ‘Other’ and we will contact you.

Receive Parts

Our manufacturing experts will print your part and ship it out. You will receive an email when your part starts to print and a tracking number when it has shipped.

Take your designs from prototype to production

with Nebula 3D on-demand 3D printing service

Expertise

As two experienced manufacturing engineers with degrees in mechanical and electromechanical engineering, we work together with CAD designers, additive manufacturing engineers, and skilled 3D printing technicians. Our main goal is to carefully create prototypes that match specific requirements.

At Nebula 3D, our team’s know-how comes from years of experience in making advanced materials, working in mechanical and Electrical engineering, and understanding materials like plastics really well.

Nebula 3D prides itself on being a fabrication partner from start to finish. After inspection and quality assurance, our team can assemble, pack, and ship your product. Our kitting service ensures that every part you need is delivered on time and undamaged. This service reduces customers’ labor and inventory costs, while increasing productivity and cash flow.

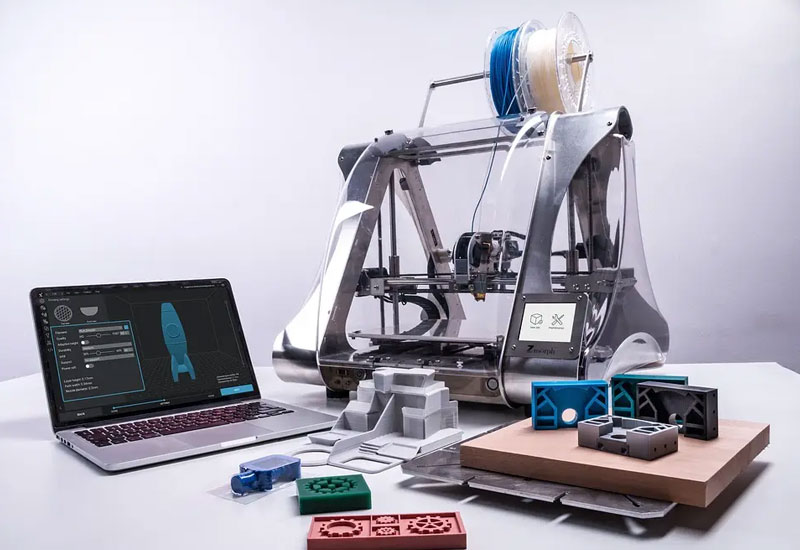

Technology & Materials

Nebula 3D, located in Boston, MA, operates with a full suite of SLS, SLA, FDM, and DLP 3D printing technologies.

Choose from a wide variety of materials, including nylon, PLA, and carbon fiber-reinforced ABS. Unsure about which material suits your application best? No worries! Our experts can guide you through material selection and post-processing options to ensure that your part attains the desired properties and finish.

Prototyping

On-Demand Design

Accelerate your time to market by leveraging Nebula3D’s proficient design and engineering CAD service, even if you lack a 3D CAD file.

Reverse Engineering

The process of reverse engineering involves transforming an existing physical object into a 3D CAD model. Our service team efficiently conducts 3D scans of small or large objects, both on-site and off-site, to generate CAD models for prototypes and legacy parts.

Printing Technology

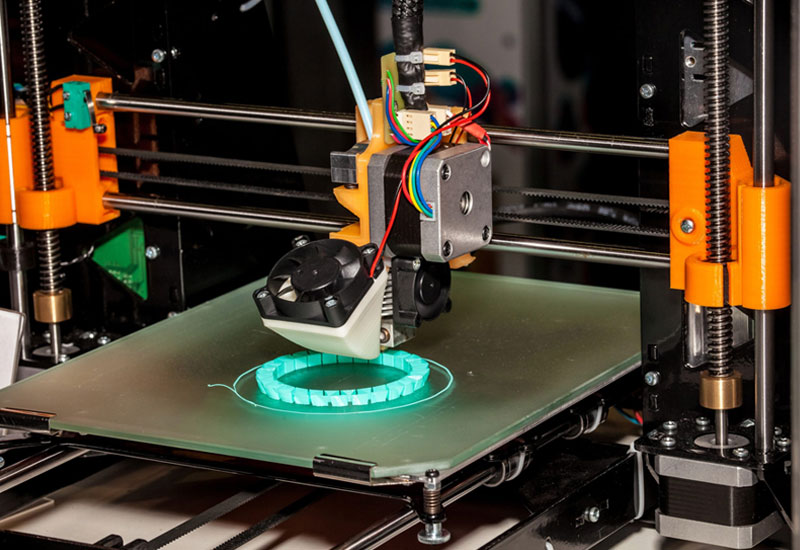

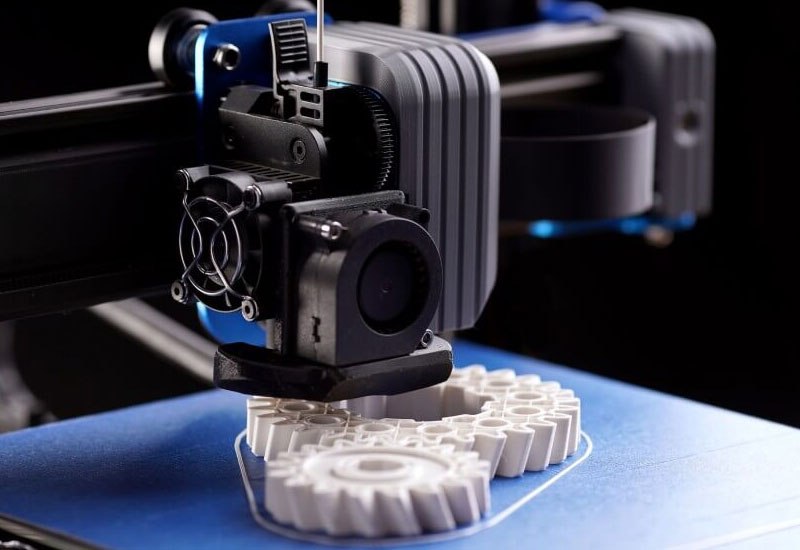

Fused Deposition Modeling (FDM)

Also known as fused filament fabrication (FFF), FDM is the most widely used method of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers. This technique is well-suited for basic proof-of-concept models and quick, low-cost prototyping of simple parts, such as parts that might typically be machined.

Stereolithography (SLA)

Invented in the 1980s, SLA was the world’s first 3D printing technology. It is still one of the most popular technologies for professionals today. SLA printing produces parts with the highest resolution and accuracy, the clearest details, and the smoothest surface finishes. Resin 3D printing is a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. SLA parts can also be highly polished and/or painted after printing, resulting in client-ready parts with custom finishes.

Selective Laser Sintering (SLS)

Coming Soon

Digital Light Processing (DLP)

Coming Soon